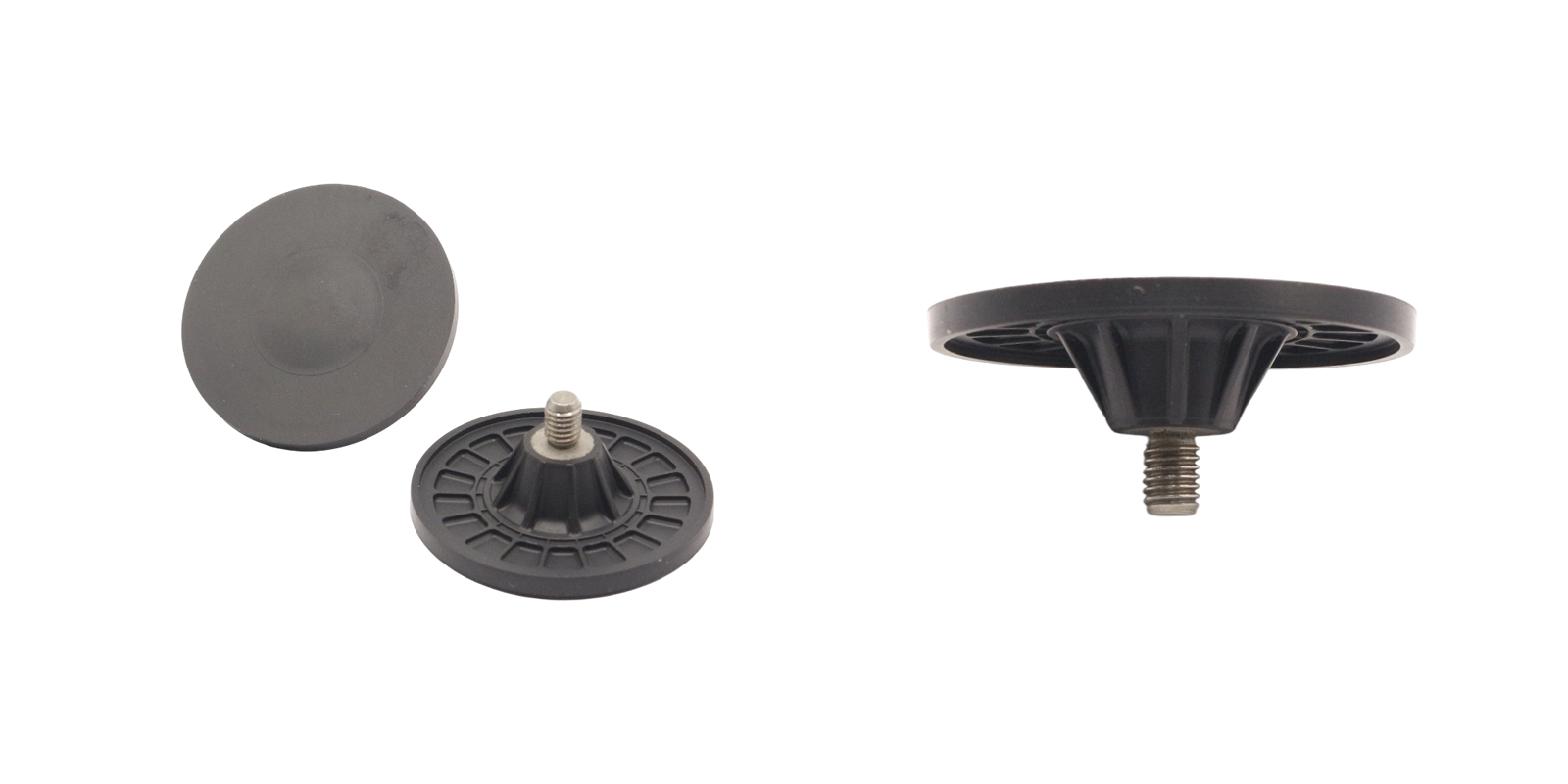

This is a Screw Rubber Diaphragm for Air Pump. It’s completely black. It has a disc-shaped composite structure. Its surface is smooth and uniform. It has the soft texture unique to rubber. One side of the diaphragm is a flat circular rubber surface. The other side has a metal screw stud.The rubber around the screw stud is conical. It has a regular hollowed-out reinforcing rib design. Its edges are regular. Its dimensions are precise. This lets it fit the power assembly of air pumps accurately. It realizes gas compression and sealing. It’s a practical functional component in air pump systems.It’s a core power and sealing part in pneumatic systems. It’s an important member of Diaphragms & Sealing Gaskets and

Gasket & Membrane Assemblies. It meets the performance requirements of

Sealed Diaphragm Pump and

Pressure Seal Components.

Product Features

1. Function:In air pump systems, this screw-equipped rubber diaphragm mainly takes on the core roles of gas compression, transmission and sealing.It realizes gas suction and discharge through reciprocating deformation. It provides a stable air source for pneumatic tools, inflation devices and other equipment. It also seals the air pump chamber tightly. This prevents gas leakage. It ensures the stability and efficiency of air pump pressure output. Its functional performance matches the requirements of

Sealed Fluid Transfer Pump and Mini Sealed Valve in pneumatic control systems.

?

2. Performance Characteristics

1)Sealing ReliabilityThe rubber material has high elasticity. This lets it fit tightly with the air pump chamber. It forms a gap-free sealing barrier. Even during high-frequency reciprocating movement, it blocks gas leakage effectively. It ensures stable air pump pressure. This performance meets the strict standards of

Fluid-Tight Diaphragms and

Sealing Elements for Valves.

2)Wear ResistanceIts surface texture is uniform. When it rubs against internal air pump components, there’s minimal wear. It can maintain structural integrity after long-term high-frequency work. This extends the service life of the air pump. This durability meets the service life requirements of

Micro Sealed Hydraulic Pump supporting components in high-cycle operations.

3)Elasticity and Deformation RecoveryRubber has high elasticity. This lets it be repeatedly compressed and rebounded during the air pump's working cycle. After deformation, it can quickly return to its original shape. This ensures the stability of gas compression and transmission efficiency. This elastic performance meets the dynamic response requirements of Diaphragms & Sealing Gaskets and flexible pneumatic components.

4)Metal Screw AdaptabilityThe integrated metal screw stud has precise dimensions. It enables firm connection with air pump power components (such as connecting rods, drive shafts). During movement, it won’t loosen or shift. This ensures stable power transmission. This fitting precision is like the manufacturing standards of

Sealed Fluid Direction Control Valve and high-precision power transmission components.

5)Weather and Temperature ResistanceIt can adapt to the conventional operating temperature range of air pumps. Under normal temperature or slightly high-temperature working conditions, the rubber won’t age or harden. The metal screw stud won’t rust. It maintains stable performance. This environmental adaptability meets the standards of Pressure Seal Components in general industrial environments.

6)Chemical StabilityIt can stand the erosion of media such as air and oil-gas. After long-term contact, it won’t swell or degrade. It’s suitable for air pump systems in various pneumatic scenarios. This chemical stability meets the material compatibility requirements of Gasket & Membrane Assemblies in pneumatic media environments.