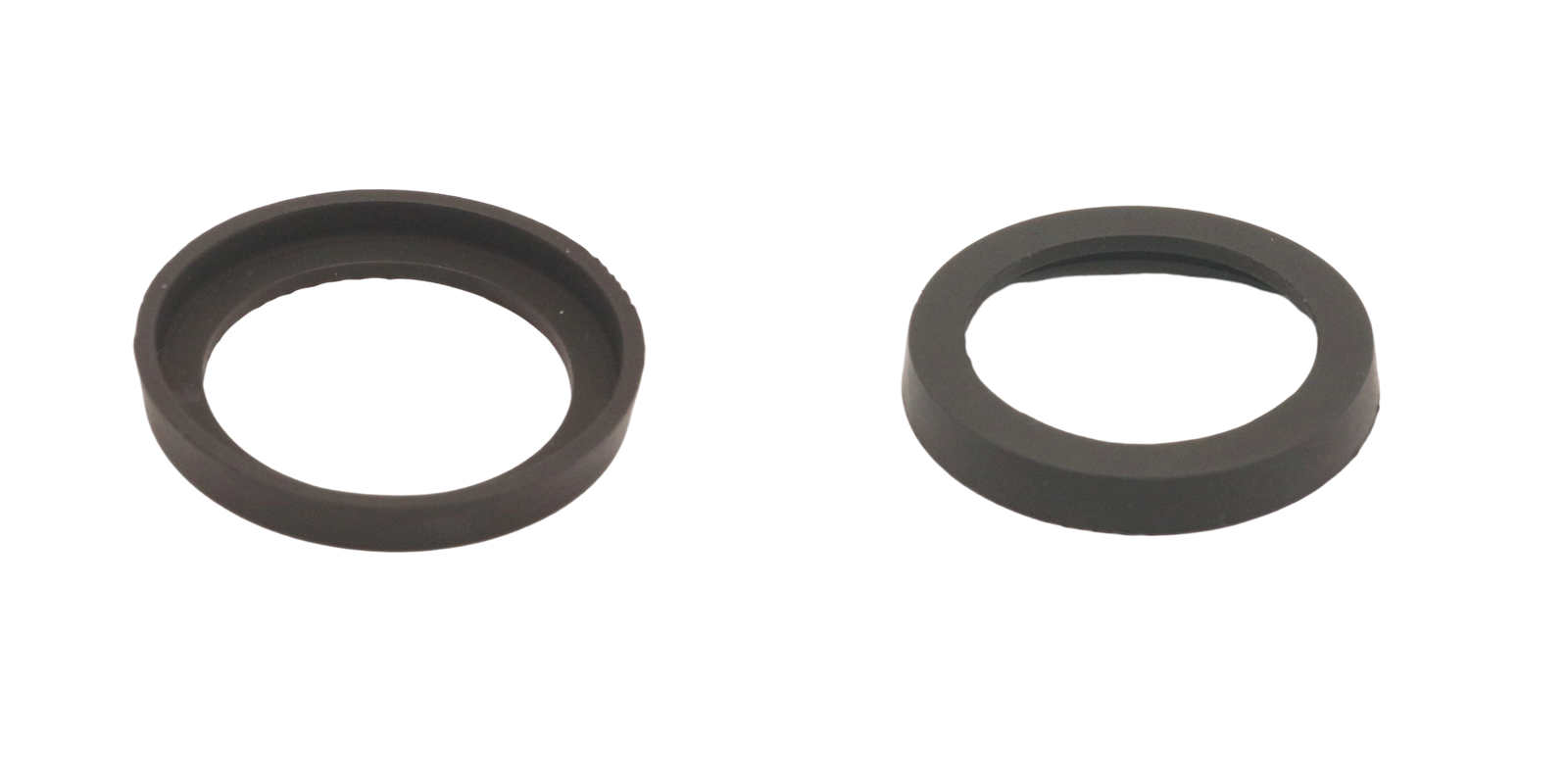

This is a Fluid-Tight Rubber Diaphragm for hydraulic pumps. It’s completely black. It has a circular rubber structure. Its surface is smooth and uniform. It has the soft texture unique to rubber. Its edges are regular. Its thickness is uniform. Its shape is symmetrical.?Its overall dimensions are precise. This lets it fit the corresponding fluid equipment interfaces accurately. It realizes fluid sealing and isolation. It’s a practical functional sealing component in industrial fluid systems.?It’s a core sealing part in fluid control systems. It’s an important member of Diaphragms & Sealing Gaskets and

Gasket & Membrane Assemblies. It meets the performance requirements of

Sealed Diaphragm Pump and

Pressure Seal Components.?

1. Function?:In fluid systems, the Fluid-Tight Rubber Diaphragm mainly takes on the core roles of fluid sealing and isolation. It can fit tightly at the interfaces of fluid equipment and pump components it blocks fluid (liquid or gas) leakage effectively. This ensures the tightness and pressure stability of the system hand,it isolates different fluid media or equipment components. This prevents medium mixing or interference between parts.?This ensures the normal operation of fluid systems (such as chemical transmission, hydraulic systems, water treatment equipment). It also guarantees the accuracy of fluid transmission. This is consistent with the functional demands of

Sealed Fluid Transfer Pump and Mini Sealed Valve in industrial fluid circuits.?

?

2. Performance Characteristics?

1)Reliable Fluid Sealing Performance?:The rubber material has high elasticity. This lets it fit tightly with equipment interfaces. It forms a gap-free sealing barrier. It blocks fluid leakage effectively. Even under conditions of pressure fluctuation or equipment vibration, it maintains stable sealing performance. This ensures the safety and efficiency of the fluid system. This performance meets the strict standards of

Fluid-Tight Diaphragms and

Sealing Elements for Valves.?

2)Precise Dimensional Adaptation?:It’s manufactured strictly in accordance with the specifications of fluid equipment. The circular or semi-circular contour has extremely high dimensional precision. It can match the design parameters of equipment interfaces perfectly. After installation, it’s not easy to fall off or shift. This ensures the stability of sealing and isolation functions. It avoids sealing failure caused by dimensional deviations. This precision is comparable to the manufacturing standards of

Sealed Fluid Direction Control Valve and high-precision fluid components.?

3)Fluid Corrosion Resistance?:It can withstand the erosion of various fluid media (such as acids, alkalis, water, oils, organic solvents). After long-term contact, it won’t swell, age, or crack. It maintains stable performance. It’s suitable for fluid systems in multiple fields such as chemical industry, hydraulics, and water treatment. This corrosion resistance meets the durability requirements of

Micro Sealed Hydraulic Pump supporting components in harsh media environments.?

4)Good Elasticity and Deformation Recovery?:The rubber material gives it excellent elasticity. When fluid pressure changes or equipment components shift slightly, it can achieve tight sealing through moderate deformation. After deformation, it can quickly return to its original shape. It maintains sealing performance after multiple uses. It adapts to the dynamic working conditions of fluid systems. This elastic performance meets the dynamic response requirements of Diaphragms & Sealing Gaskets and flexible sealing parts.?

5)Strong Temperature Resistance?:It can adapt to a wide temperature range (-40℃~120℃, with slight differences depending on the material). In scenarios such as high-temperature fluid transmission or low-temperature storage, it won’t harden, become brittle, or soften and deform. It maintains stable elasticity and sealing performance. This temperature adaptability meets the standards of Pressure Seal Components in extreme temperature working conditions.?

6)Wear Resistance and Durability?:Its surface texture is uniform. When it rubs against equipment components, there’s minimal wear. During long-term use, it can maintain structural integrity. This ensures the continuity of sealing and isolation functions. It extends the maintenance cycle of fluid equipment. This durability is consistent with the service life requirements of Gasket & Membrane Assemblies in high-cycle fluid systems.