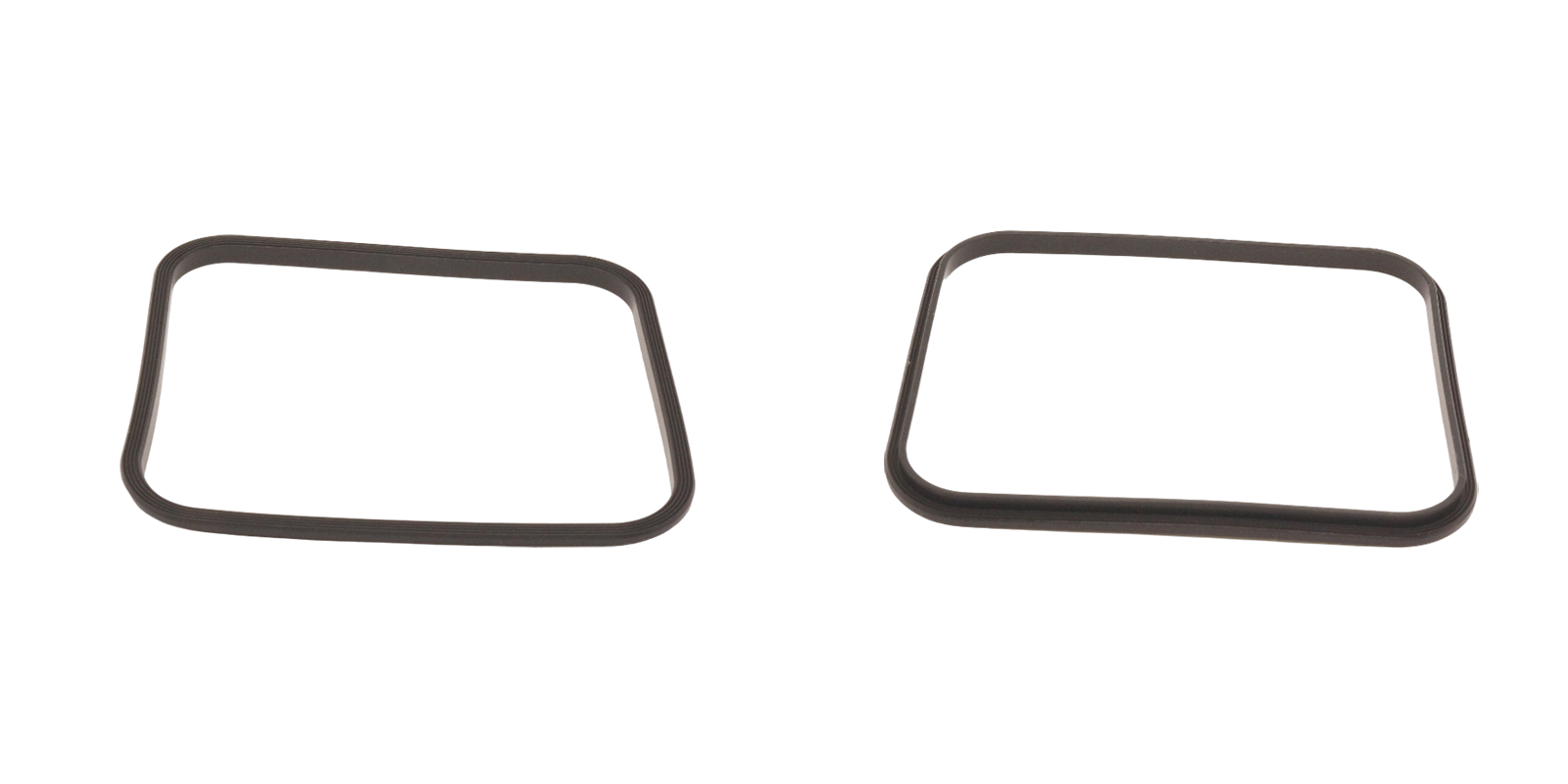

This is a Sealing Gasket for Aesthetic Medical Equipment. It’s a black square component. It’s made of EPDM. It’s processed via peroxide vulcanization. Its hardness is tailored for aesthetic medical scenarios.It has a regular square ring structure. The corners are rounded. Its surface is delicate and matte. Its cross-sectional thickness is uniform. It has fine textures. Its edges are smooth, with no burrs. It boasts excellent flexibility. It can be bent and deformed flexibly. Its dimensions are precise. It perfectly fits the sealing interfaces of aesthetic medical equipment. It serves as a precision accessory integrating sealing performance and adaptability.As a core sealing part for aesthetic medical devices, it is an integral component of

Specialized Accessories For Aesthetic Medical Equipment and

Aesthetic Machine Components. It meets the precision and safety standards of

Medical Device Seals and Aesthetic Device Seals.

Product Features

1.Function:This square ring-shaped sealing gasket—crafted from EPDM via peroxide vulcanization with hardness optimized for aesthetic medical applications—is the "core interface sealing and protection component" for aesthetic medical equipment. Its primary role is to provide high-airtightness sealing protection for the chamber and pipeline interfaces of aesthetic devices.It embeds tightly into the square interface gaps of equipment. It blocks the intrusion of external dust, moisture, and contaminants into the device interior. This prevents pollution or dampness of precision components (such as laser emission modules and liquid injection pipelines) in aesthetic medical equipment. It also prevents leakage of internal media (e.g., coolants, skincare serums).This ensures the safety of aesthetic treatment processes and the stability of equipment operation. Its protective function matches the requirements of Beauty Equipment Gaskets and Cosmetic Instrument Parts in professional aesthetic medical settings.

?

2. Performance Characteristics

1)Superior Sealing and ProtectionEPDM material combined with peroxide vulcanization endows it with high elasticity and tight fit. It can fully fill micro-gaps in aesthetic medical equipment interfaces. It achieves IP65-level dust and water resistance. It effectively resists moisture and dust intrusion in treatment environments. It protects internal precision components of the equipment. This performance meets the strict standards of

Medical Grade Silicone Seals and

Sterile Medical Seals.

2)Process-Enhanced StabilityPeroxide vulcanization ensures uniform crosslinking of EPDM. It results in stable physical properties. It is not prone to deformation or aging during long-term use. It adapts to the high-frequency startup/shutdown and operational demands of aesthetic medical equipment. This stability meets the durability requirements of Aesthetic Device Seals and high-cycle medical equipment components.

3)High Biocompatibility and SafetyEPDM material complies with medical-grade biocompatibility standards. It undergoes no chemical reactions or leaching when in contact with human care media (such as conductive serums) used in aesthetic equipment. It meets the safety and hygiene requirements of aesthetic medical scenarios. This biocompatibility matches the safety specifications of

Medical Silicone Seal and

Medical Vial Cap Seals for human-contact applications.

4)Strong Temperature Resistance and Environmental AdaptabilityIt withstands a wide temperature range of -30℃~120℃. It adapts to working temperature scenarios of aesthetic equipment such as cooling and heating. It also exhibits UV and ozone aging resistance. When long-term exposed to light environments in aesthetic treatments, there’s no material degradation. This adaptability meets the environmental requirements of Aesthetic Machine Components in professional clinics.

5)Outstanding Medium CompatibilityIt can withstand common media in aesthetic medical equipment, including skincare serums, cleaning agents, and mild oils. No swelling or performance attenuation occurs after contact. It adapts to the daily cleaning and maintenance needs of the equipment. This compatibility meets the material standards of Beauty Equipment Gaskets and integrated aesthetic device systems.

6)Excellent Flexibility and AdaptabilityThe material itself possesses good flexibility. It can adapt to minor dimensional errors of aesthetic equipment interfaces. After installation, there’s no displacement or missing seals. Combined with the durability of peroxide vulcanization, it is not easily damaged by repeated assembly, disassembly, or extrusion. It supports long-term stable use of the equipment. This adaptability is like the precision standards of Specialized Accessories for Aesthetic Medical Equipment and custom-fit medical components.