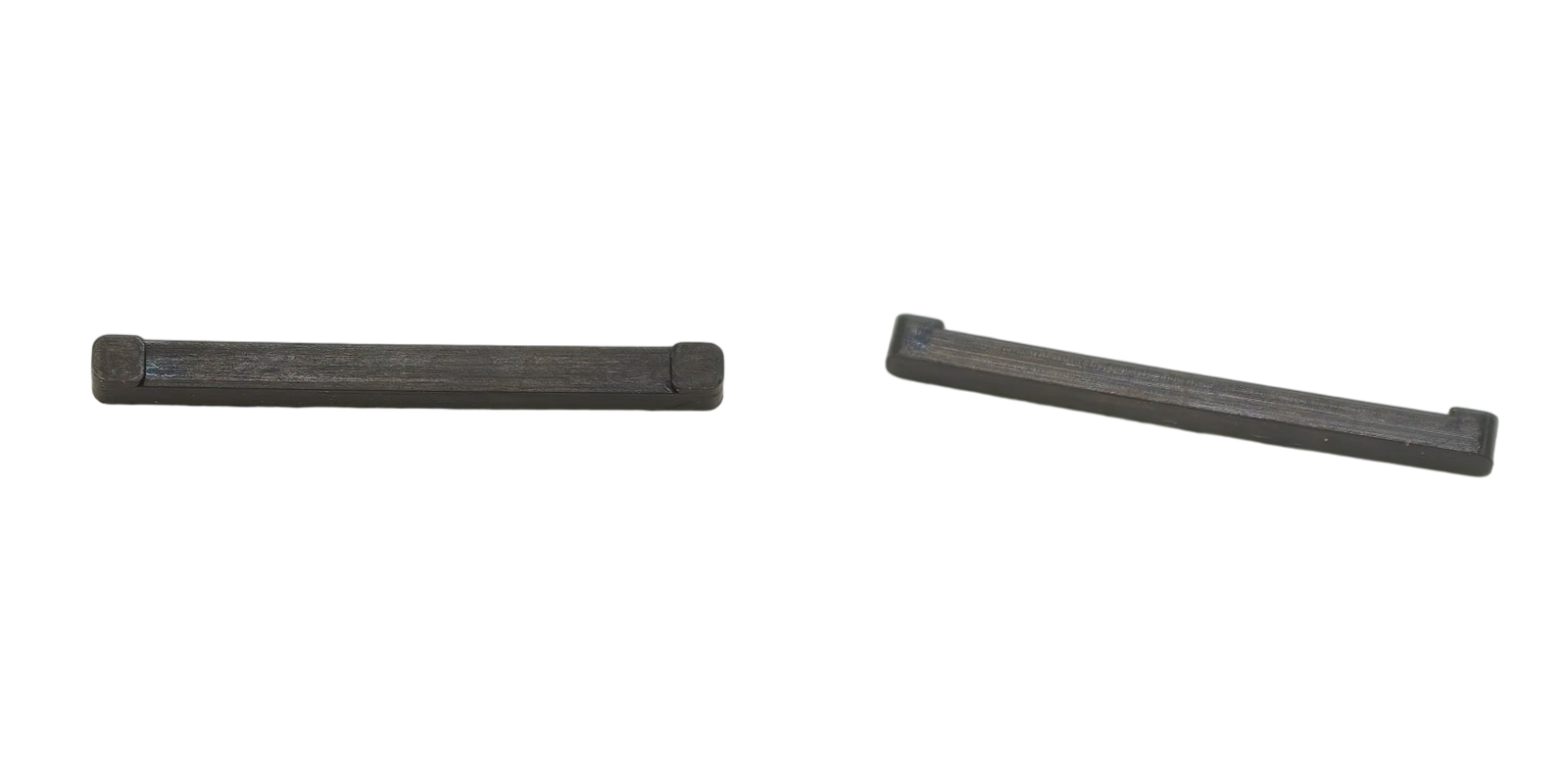

This is an EPDM Rubber Sealing Strip for electronic devices. It’s a black elongated rubber component. It’s made of EPDM. Its hardness is 60±5°A.?It has a slender rectangular rod shape. Both ends have small raised positioning structures. Its surface is delicate and matte. Its edges are regular, with no burrs. Its cross-sectional thickness is uniform. Its dimensional precision is high. It is flexible to adapt to gap sealing scenarios of electronic equipment. It serves as a precision rubber accessory integrating sealing and positioning functions.?As a specialized sealing product in the

Electronic Devices Industry, it meets the application standards of

Sealing Accessories For Electronic Devices and

Electronic Sealing Components. It is widely used in the

Electronic Equipment Industry and

Electronic Devices Sector.?

Product Features?

1.Function?:This elongated EPDM rubber sealing strip (hardness 60±5°A) is a "gap sealing protection component" in the Electronic Devices Industry. Its core function is to fill the slender gaps of electronic equipment casings and module interfaces. It achieves integrated sealing, buffering, and protection.?It embeds tightly into the elongated gaps of equipment. It blocks the intrusion of external dust, moisture, and tiny impurities into the equipment interior. This avoids short circuits and corrosion of electronic components. It leverages the elasticity of rubber. This buffers slight vibrations during equipment operation or transportation. It reduces component wear.?The positioning structures at both ends ensure installation accuracy. This maintains the operational stability of electronic equipment in complex environments. Its multi-functional protection matches the requirements of

Electronic Device Seals and

Electronics Waterproof Parts in electronic system protection.?

?

2.Performance Characteristics?

1)Outstanding Sealing and Protection?:EPDM material combined with 60±5°A hardness balances elasticity and support. It can fit the slender gaps of electronic equipment tightly. It achieves IP64-level dustproof and waterproof performance. It resists dust, splashing water, and moisture erosion in daily use effectively. It protects internal precision electronic components. This performance meets the strict standards of Electronic Sealing Components and

Electronic Equipment Sealing Components.?

2)Strong Weather and Environmental Adaptability?:EPDM material withstands a wide temperature range of -40℃~120℃. It adapts to the full scenario of electronic equipment from low-temperature storage to high-temperature operation. It also exhibits excellent UV and ozone aging resistance. During long-term use, there’s no cracking or material degradation. It has high compatibility with equipment service life. This adaptability meets the durability requirements of Electronics Waterproof Parts and electronic equipment in complex working conditions.?

3)Insulation and Medium Compatibility?:EPDM itself has high insulation. It can isolate the risk of current conduction inside electronic equipment. It also tolerates common media such as cleaning agents and mild oil stains used in electronic equipment. After contact, there’s no swelling or performance attenuation. This dual performance matches the safety and maintenance requirements of Sealing Accessories for Electronic Devices in electronic systems.?

4)Precise Installation and Positioning?:The raised positioning structures at both ends can fit with the card slots of equipment gaps accurately. After installation, there’s no displacement or loosening. It adapts to various electronic equipment with elongated sealing interfaces (such as communication equipment casings, industrial computer module joints). This precision is like the manufacturing standards of Electronic Sealing Components and high-precision electronic accessories.?

5)Excellent Toughness and Durability?:60±5°A hardness balances flexibility and deformation resistance. It can adapt to minor dimensional errors of equipment gaps. It resists breakage after repeated assembly and disassembly. It has a low friction coefficient and wear rate with equipment components. It supports long-term use and maintenance operations of electronic equipment. This durability meets the service life requirements of Electronic Equipment Sealing Components and long-term service electronic accessories.